Introduction to Wire Mesh in Aerospace

The aerospace industry has always been at the forefront of innovation, constantly pushing the limits of technology to achieve new heights in flight and space exploration. In recent years, wire mesh has emerged as a revolutionary material that is transforming how aerospace components are designed and manufactured. From structural and thermal applications to noise reduction and contamination prevention, wire mesh is used in various ways to improve the safety, reliability, and efficiency of aerospace components. In this article, we will explore the multiple applications of wire mesh in aerospace and its unique properties that make it an essential material for the future of flight and space exploration.

Applications and Examples of Wire Mesh in Aerospace

Aircraft Components: Wire mesh is often used as a reinforcing material in composite materials used in aircraft manufacturing. This provides additional strength and stiffness to structural components like wing spars and fuselage frames. Copper wire mesh has the crucial role of providing lighting protection to airplanes by providing a protective layer around the aircraft, disbursing the electricity protecting the internal electrical components and the passengers from harm. Air filters on planes also use wire mesh to ensure high air quality since passengers and crew need to breathe recirculated and pressurized air on high-altitude, lengthy flights.

Aircraft Engine Components: Wire mesh is used as a reinforcement material in composite materials used in aircraft engine components, providing additional strength and stiffness to the structure. It helps meet noise regulations with anti-vibration and electro-compatibility. It is also used as a thermal protection material, helping to protect sensitive engine components from the extreme temperatures encountered during flight. Wire mesh plays a crucial role in preventing contamination by filtering dirt and debris from getting into critical systems, which could otherwise cause an engine overhaul during the flight.

Satellite Antennas: Wire mesh is used as the antenna reflector material to manufacture satellite antennas. It provides a lightweight and highly durable surface for reflecting radio waves. Wire mesh is also used as the supporting structure for the antenna, providing the required level of stiffness and strength.

Spacecraft: Wire mesh is extensively used to manufacture satellites and spacecraft. It is often used as a thermal protection material, protecting sensitive electronics and other components from the extreme temperatures encountered in space. Wire mesh can also be used as a shielding material to protect against electromagnetic interference (EMI) and other forms of radiation. An example of wire mesh being applied here is in manufacturing satellite antennas. Wire mesh is used as the antenna reflector material, providing a lightweight and highly durable surface for reflecting radio waves.

Benefits of Using Wire Mesh in Aerospace

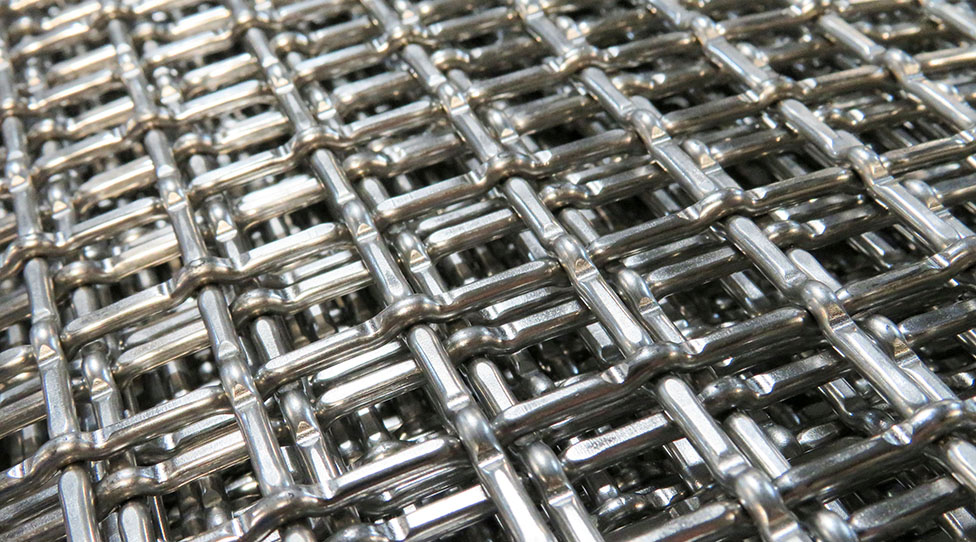

One of the primary benefits of using wire mesh in aerospace applications is its lightweight and high strength-to-weight ratio. Wire mesh is much lighter than traditional metal materials like aluminum or steel, making it an ideal choice for applications where weight is a critical factor, such as in the manufacture of aircraft and spacecraft.

Another benefit of wire mesh is its flexibility and durability. Wire mesh is highly flexible, allowing it to be easily formed into various shapes and sizes. This makes wire mesh an ideal choice for use in complex aerospace structures, where traditional materials may not be able to provide the required level of flexibility.

In addition, wire mesh is highly durable and resistant to wear and tear. This makes it an ideal choice for aerospace applications, where components are exposed to extreme temperatures, vibration, and other harsh conditions. Wire mesh is also resistant to corrosion, which makes it a good choice for use in applications where exposure to moisture or other corrosive substances is a concern.

Why Choose Universal Wire Cloth

As we’ve seen throughout this article, wire mesh is a critical component in the aerospace industry, providing benefits such as noise reduction, contamination prevention, lightweight construction, flexibility, and durability. Companies such as Universal Wire Cloth have been at the forefront of providing innovative wire mesh solutions for the aerospace industry. With over 45 years of experience in the wire mesh industry, Universal Wire Cloth has become a trusted partner with many of the top aerospace companies in the world, offering a wide range of wire mesh products and customized solutions to meet their unique needs. As technology continues to evolve, companies like Universal Wire Cloth will continue to play a critical role in developing new aerospace technologies and the industry’s continued success.