Wire Mesh as Ventilation

Wire mesh is a versatile material with a wide range of applications across various industries. One of its most common uses is as a ventilation system component.

Ventilation is crucial in any building or structure, as it helps regulate temperature, control humidity, and improve air quality. Wire mesh is an effective solution for providing ventilation in buildings, as it allows air to circulate freely while keeping out debris and pests.

Whether you’re an architect, engineer, or property owner, understanding the role of wire mesh in ventilation systems can help you make informed decisions about your building’s infrastructure.

What types of wire mesh are suitable for ventilation systems?

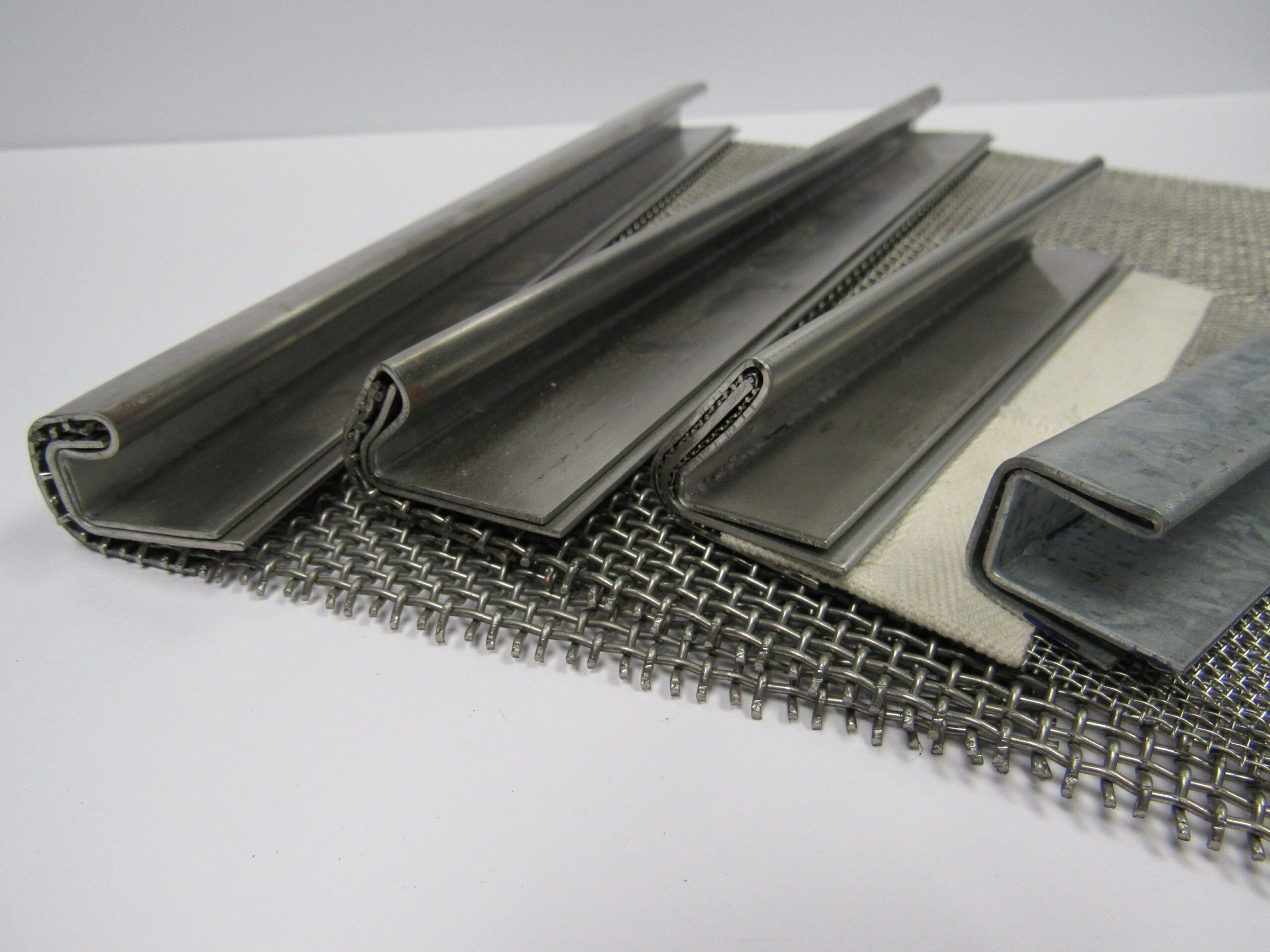

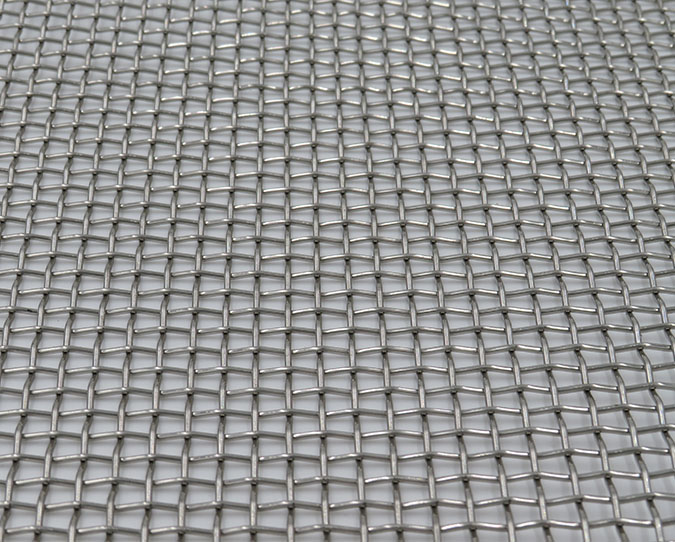

The two main types of wire mesh used in ventilation systems are welded and woven wire mesh. The type of wire mesh used will depend on factors such as the level of filtration required, the size and shape of the ventilation opening, and the operating environment.

Benefits of wire mesh in ventilation systems

Wire mesh offers numerous benefits when used in ventilation systems. Below are some of the advantages of incorporating wire mesh in your building’s ventilation design:

- Improved Airflow: Wire mesh promotes better airflow than other ventilation materials, such as slotted or solid panels. Its porous structure allows air to pass through freely, which helps regulate temperature and humidity levels in the building.

- Enhanced Structural Strength: Wire mesh provides additional structural support to the building’s ventilation system. It adds rigidity and stability to the ductwork, reducing the risk of sagging or collapse.

- Increased Safety and Security: Wire mesh can prevent debris, insects, and animals from entering the ventilation system. This is particularly important in industrial and agricultural facilities, where dust, dirt, or harmful particles may contaminate the air intake.

- Durability and Longevity: Wire mesh is a durable material that can withstand harsh weather conditions and regular wear and tear. It has a long lifespan and requires minimal maintenance, making it a cost-effective solution for ventilation systems.

- Aesthetics: Wire mesh can add a visually interesting texture, provide a modern or industrial look, and hide or camouflage the ventilation system to create a cohesive design.

These advantages make wire mesh a popular choice for architects, engineers, and building owners who prioritize efficient and effective ventilation.

Applications of wire mesh in ventilation systems

Now that we know how wire mesh used in ventilation systems is beneficial, let’s look at common areas where it is applied. Wire mesh is used in ventilation systems in various types of buildings, including residential and commercial buildings, industrial facilities, and agricultural structures.

Residential Buildings: Wire mesh can be used in homes for ventilation in areas such as attics, basements, and crawl spaces. It can help regulate temperature and prevent moisture buildup, which can lead to mold and mildew growth.

Commercial Buildings: In commercial buildings, wire mesh can be used in HVAC systems to filter out dust, dirt, and other contaminants from the air. It can also be used as screens for windows and doors to provide ventilation while keeping out insects and other pests.

Industrial Facilities: Wire mesh is commonly used in industrial facilities for ventilation in warehouses, factories, and manufacturing plants. It can help regulate temperature and humidity levels, reduce the risk of airborne contaminants, and prevent machinery from overheating.

Agricultural Structures: In agricultural facilities such as barns and stables, wire mesh can be used in ventilation systems to regulate temperature and improve air quality. It can also prevent pests and animals from entering the building.

Installation and Maintenence

Wire mesh can be installed in ventilation systems by attaching it to ductwork, framing, or other support structures using fasteners such as screws or clamps. Proper installation techniques and tools are required to ensure the wire mesh is securely in place and does not sag or buckle over time.

It should be inspected regularly for damage or wear and cleaned as needed to remove any accumulated debris or contaminants. Proper maintenance can extend the lifespan of the wire mesh and ensure that the ventilation system operates efficiently.

Why Choose Universal Wire Cloth

In conclusion, wire mesh is an effective and efficient solution for ventilation systems in various buildings and structures.

If you are looking for a reliable, experienced company that provides high-quality wire mesh products for ventilation systems, choose Universal Wire Cloth.

With over 45 years of experience, Universal Wire Cloth offers a wide range of wire mesh products designed to meet the specific needs of different industries and applications.

Our commitment to customer satisfaction and focus on quality and innovation make us a top choice for wire mesh products for ventilation systems.

Contact Universal Wire Cloth today to learn more about our products and services and how they can help you achieve optimal ventilation in your building.